Importance of Alkynes : Acetylene

Commercial Importance of Alkynes : Acetylene and Methylacetylene

Uses of Acetylene and Methylacetylene

– Acetylene is by far the most important commercial alkyne.

– and Acetylene is an important industrial feedstock, but its largest use is as the fuel for the oxyacetylene welding torch.

– It is a colorless, foul-smelling gas that burns in air with a yellow, sooty flame.

– When the flame is supplied with pure oxygen, however, the color turns to light blue, and the flame temperature increases dramatically.

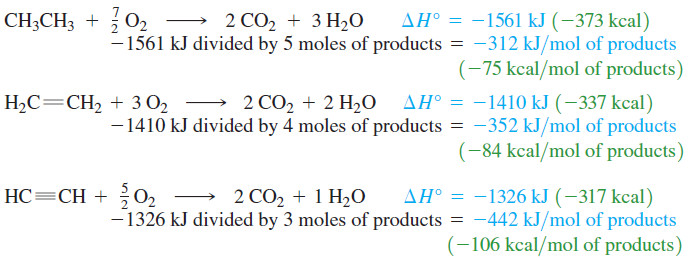

– A comparison of the heat of combustion for acetylene with those of ethene and ethane shows this gas makes an excellent fuel for a high-temperature flame.

– If we were simply heating a house by burning one of these fuels, we might choose ethane as our fuel because it produces the most heat per mole of gas consumed.

– In the welding torch, we want the highest possible temperature of the gaseous products.

– The heat of reaction must raise the temperature of the products to the flame temperature.

– Roughly speaking, the increase in temperature of the products is proportional to the heat given off per mole of products formed.

– This rise in temperature is largest with acetylene, which gives off the most heat per mole of products.

– The oxyacetylene flame reaches temperatures as high as 2800 °C.

– When acetylene was first used for welding, it was considered a dangerous, explosive gas.

– Acetylene is thermodynamically unstable.

– When the compressed gas is subjected to thermal or mechanical shock, it decomposes to its elements, releasing 234 kJ (56 kcal) of energy per mole.

– This initial decomposition often splits the container, allowing the products (hydrogen and finely divided carbon) to burn in the air.

– Acetylene is safely stored and handled in cylinders that are filled with crushed firebrick wet with acetone.

– Acetylene dissolves freely in acetone, and the dissolved gas is not so prone to decomposition.

– Firebrick helps to control the decomposition by minimizing the free volume of the cylinder, cooling and controlling any decomposition before it gets out of control.

– and Methylacetylene also is used in welding torches.

– Methylacetylene does not decompose as easily as acetylene, and it burns better in air (as opposed to pure oxygen).

– Methylacetylene is well suited for household soldering and brazing that requires higher temperatures than propane torches can reach.

– The industrial synthesis of methylacetylene gives a mixture with its isomer, propadiene (allene).

– This mixture is sold commercially under the name MAPP® gas (MethylAcetylene-ProPadiene).

(2) Manufacture of Acetylene

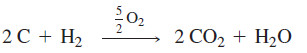

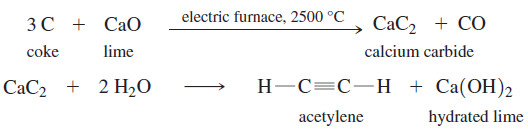

– Acetylene, one of the cheapest organic chemicals, is made from coal or from natural gas.

– The synthesis from coal involves heating lime and coke (roasted coal) in an electric furnace to produce calcium carbide.

– Addition of water to calcium carbide produces acetylene and hydrated lime.

– This second reaction once served as a light source in coal mines until batterypowered lights became available.

– A miner’s lamp works by allowing water to drip slowly onto some calcium carbide.

– Acetylene is generated, feeding a small flame where the gas burns in air with a yellow flickering light.

– Unfortunately, this flame ignites the methane gas commonly found in coal seams, causing explosions.

– Battery-powered miner’s lamps provide better light and reduce the danger of methane explosions.

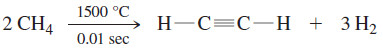

– The synthesis of acetylene from natural gas is a simple process. Natural gas consists mostly of methane, which forms acetylene when it is heated for a very short period of time.

– Although this reaction is endothermic, there are twice as many moles of products as reactants.

– The increase in the number of moles results in an increase in entropy, and the (-TΔS) term in the free energy (ΔG = ΔH – TΔS) predominates at this high temperature.